Bioplastics & Recycled Plastics: How Sustainable Materials Are Reshaping Footwear

They are revolutionizing footwear sole production, offering sustainable solutions without compromising quality or performance. From bio-based TPU to recycled EVA, discover how green innovation is shaping the future of shoes.

Sustainability Driving Change in Footwear

In today’s fashion and manufacturing landscape, sustainability has moved from a trend to a strategic necessity. The circular production of footwear was a central theme at the 2023 XXI UITIC International Conference (International Union of Shoe Industry Technicians), which explored “Towards Sustainability through Innovation”.

With rising consumers awareness, stricter sustainability regulations and cost of fossil-based polymers, brands, formulators and makers are being pushed to rethink design, materials and technologies to reduce footwear industry’s environmental footprint.

Bioplastics and recycled plastics in shoe sole production are becoming key drivers of change, helping shape a greener future for footwear industry. Sole production relies on a wide variety of polymers — EVA, TPU, polyurethanes and rubbers — and each choice directly affects carbon footprint, end-of-life options and circularity. Replacing virgin plastics with bio-based or recycled alternatives reduces fossil feedstock demand and can lower product lifecycle emissions.

Bioplastics and recycled plastics markets continue to rise steadily. Global bioplastics production is set to increase significantly from around 2.47 million tonnes in 2024 to approximately 5.73 million tonnes in 2029. The recycled plastics market size is also expanding – estimated at USD 51.70 billion in 2023 to reach USD 96.48 billion in 2030, growing at a CAGR of 9.5% from 2024 to 2030. For footwear-specific materials, thermoplastic polyurethanes (TPU) are a rapidly growing segment within the global polymer market, known for its excellent flexibility, durability and performance in footwear applications.

Bioplastics & Ricycled Plastic Explained

Bioplastics are polymers made from renewable sources (e.g. sugarcane, corn, plant oils), some of them fully biodegradable. They tipically fall into two main categories:

- Plant-Based, Non-Biodegradable

Made from renewable sources such as cellulose or vegetable oils, these materials replicate the properties of traditional plastics while lowering the carbon footprint.

2. Biodegradable

These break down through natural processes involving microorganisms. Examples include PLA, PBAT, and PHA – innovative materials already reshaping product design.

Recycled plastics, on the other hand, use post-industrial or post-consumer waste (granulated plastics, rubbers, scraps) to re-manufacture secondary raw materials, reducing virgin fossil input and waste. Though bioplastics and recycled plastics serve different purposes, contribute to a more circular and responsible production model.

Eco-friendly Footwear Materials for Sole Molding

The footwear industry is rapidly embracing biopolymers and secondary raw materials, leading an eco-conscious manifacturing transition without compromising on quality or performance. Many of these bioplastics and recycled plastics can be processed with standard injection molding equipment, producing soles with the same durability as conventional plastics but with a lighter environmental impact.

Key innovations include:

- Bio-based TPU: A renewable version of thermoplastic polyurethane — valued for its abrasion resistance, elasticity, and low weight — made from vegetable oils instead of fossil sources.

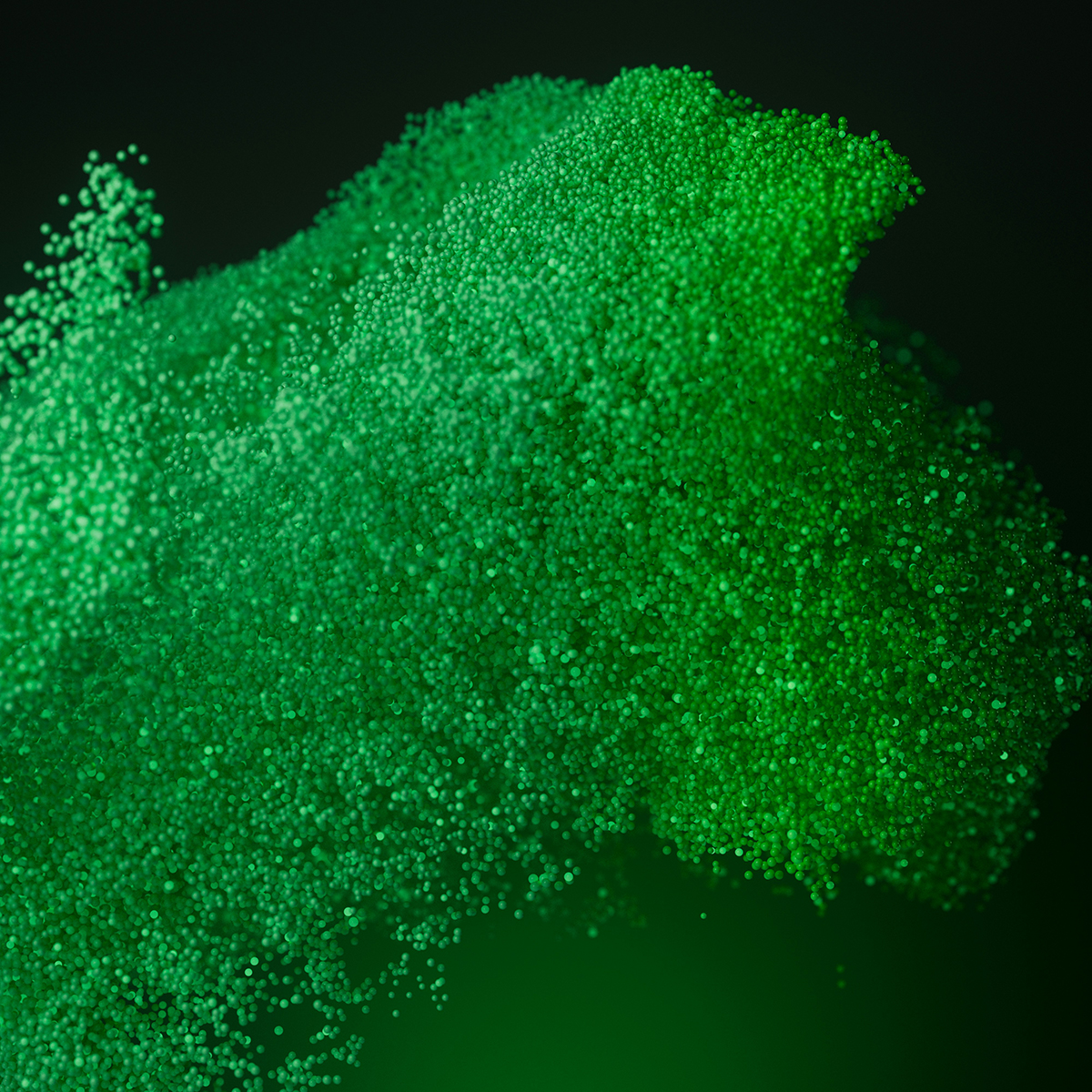

- Recycled TPU: Created by granulating production waste, this material maintains the same mechanical performance as virgin TPU, supporting circular production models.

- Bio-based or Recyclable Polyurethanes: Lightweight and comfortable, these soles are widely used in premium and athletic footwear. They can be partly bio-based or designed for recyclability.

- Bio-based EVA: Known for its flexibility and shock absorption, EVA is now available in bio-based versions that reduce reliance on fossil-derived polymers.

- Natural and recycled Rubber: Suitable for a wide range of footwear, including formal styles. Blends with recycled content further boost sustainability.

Our Commitment to Green Innovation

At Pu.Ro., our focus is not just on using sustainable materials — it’s on integrating sustainable practices throughout the product lifecycle. Here are some concrete technical and operational steps we take:

- GRS-certified bio-based and recycled TPU

- In-house granulation of production waste to reintegrate recycled TPU — protecting quality and reducing dependence on virgin materials

- R&D investment in end-of-life strategies: disassembly, recycling, possibly compostable components.

From advanced materials to eco-conscious processes, we are helping brands build the next generation of sustainable soles.

Looking for tailored, innovative, sustainable solutions for footwear sole production? Contact us to explore our sustainable materials and technologies.

- 16/09/2025

Share on social

Articles that may interest you