Polyurethane: A Brief Guide to Shoe Sole Production

Let’s discover the types, distinctive qualities and application sectors of polyurethane, with a focus on the production of shoe soles and the advantages of using polyurethane in the footwear sector

Polyurethane Characteristics and Applications

Polyurethane (PU) is a polymer that encompasses a broad class of materials used in multiple industrial sectors. From soft, low-density foams to compact elastomers, PU offers a range of shapes that meet specific needs, with applications ranging from furniture to automotive.

PU is therefore a versatile player in the world of materials with high physical-chemical performances. Its elasticity and resistance make it ideal for counteracting atmospheric, chemical and biological agents, remaining resilient even under stress.

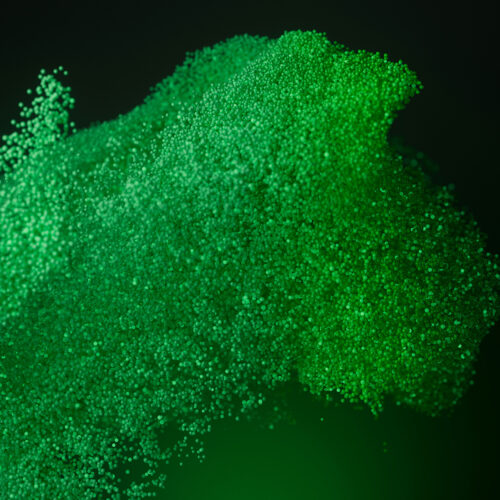

There are various types of polyurethane on the market. For example, rigid structural polyurethane foams are used in furniture and boating; rigid polyurethane foams are lightweight foams used for thermal insulation; Semi-rigid polyurethane foams are used in the automotive industry for components such as steering wheels and dashboards; flexible polyurethane foams, on the other hand, are foams used in the automotive industry and in the production of mattresses and toys. Compact polyurethane foams and elastomers are suitable for the production of shoe soles, also used for yarns, sporting goods and waterproofing. Paints and adhesives, on the other hand, are used for applications in the building and furnishing industries.

Advantages of polyurethane in the production of shoe soles

- resistance to exogenous agents (chemical, atmospheric and biological);

- impermeability water;

- lightness;

- softness;

- dimensional stability;

- mechanical resistance, abrasion and high temperatures;

- durability.

- 14/02/2024

Share on social

Articles that may interest you