DISCOVER THE DIFFERENCES BETWEEN TPU AND PU IN THE PRODUCTION OF FOOTWEAR SOLE

TPU and PU are two materials widely used in the footwear sector due to their high chemical and mechanical characteristics, but they have significant differences in properties and application. Let’s see what the characteristics and differences are.

In the footwear industry, the choice of materials for the production of soles is a crucial aspect that affects the performance, comfort and durability of the shoe. Thermoplastic polyurethane (TPU) and polyurethane (PU) are among the most used materials: they share significant chemical and mechanical characteristics, as they belong to the same family, but they also have significant differences that influence the final result. This guide aims to help industry operators make informed decisions in the production of quality footwear soles.

TPU: ROBUSTNESS, VERSATILITY AND RESISTANCE

Thermoplastic polyurethane (TPU) is known for its excellent mechanical properties. Thanks to these characteristics, TPU is one of the best performing materials for the production of different types of footwear soles (sports, casual, elegant, accident prevention, healthcare), allowing the creation of products with high-level technical and aesthetic qualities.

The main advantages of using TPU in the production of shoe soles are:

- High abrasion resistance: TPU soles are designed to last over time and are an ideal choice for shoes subject to mechanical stress or intensive use.

- Flexibility: The TPU soles offer good flexibility even at low temperatures, ensuring comfort and functionality of the shoe.

- Chemical Resistance: TPU resists substances such as oils, greases and solvents well, which are common in many industrial or outdoor environments.

- Design Versatility: TPU can be molded into different shapes and hardnesses, allowing great freedom in outsole design.

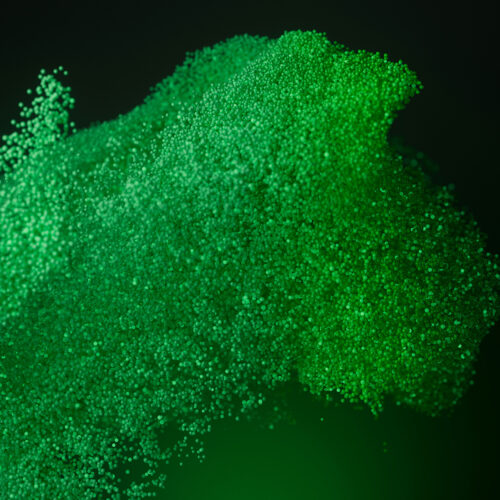

- Unlimited style options: TPU gives the possibility of applying any type of color and finish (glossy, matt, metallic, glitter, pearlescent, etc.), and of painting.

PU: COMFORT, LIGHTNESS AND DURABILITY

Good footwear should be comfortable and durable. Polyurethane meets these needs. Used to make soles, midsoles and insoles, PU is characterized by a wide range of densities that allow customization of rebound and comfort. Furthermore, its resistance to chemical, atmospheric and biological agents, together with its impermeability to water and dimensional stability, make it a reliable option.

The main advantages of using PU in the production of shoe soles are:

- Excellent Cushioning: PU offers the possibility of customizing the level of cushioning, making the fit comfortable and absorbing impacts during walking.

- Lightweight: PU allows for the production of lightweight soles for shoes that are comfortable to wear.

- Resistance to external agents: PU is known for its resistance to chemical, atmospheric and biological agents.

- Dimensional stability: PU soles maintain their technical performance over time.

- Economic factor: depending on the formulation, PU can be cheaper than TPU, an aspect to consider in large-scale production

TPU OR PU?

The choice between the use of TPU and PU in the footwear industry is a crucial decision that depends on the priorities of the brand and the specific needs of the product. Both of these materials offer a wide range of possibilities for creating high-quality soles. Understanding their differences is essential to creating footwear that meets the needs of the customer and the end consumer.

If you would like to further explore the applications of TPU and PU in the production of shoe soles or need advice for your project, contact us. We’re here to answer your questions and help you create ideal footwear for your brand.

- 19/10/2023

Share on social media

Articles that might interest you